Fiat 500 engine

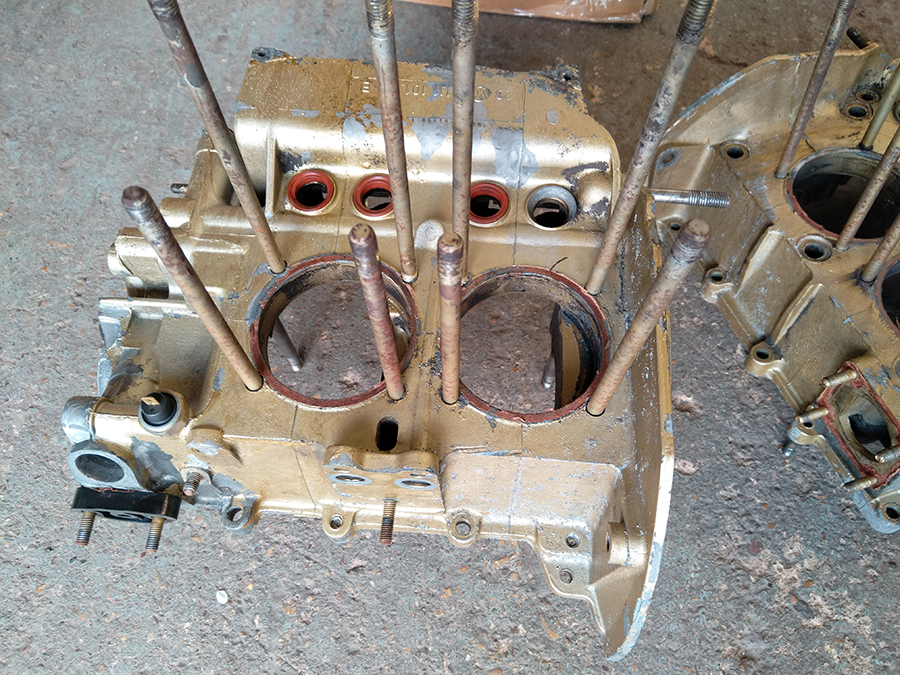

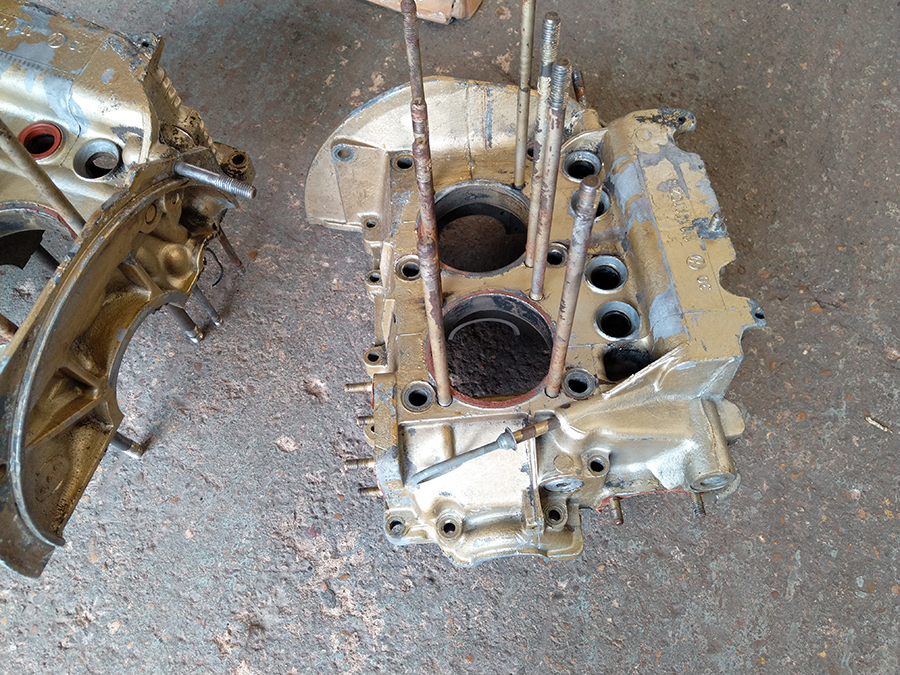

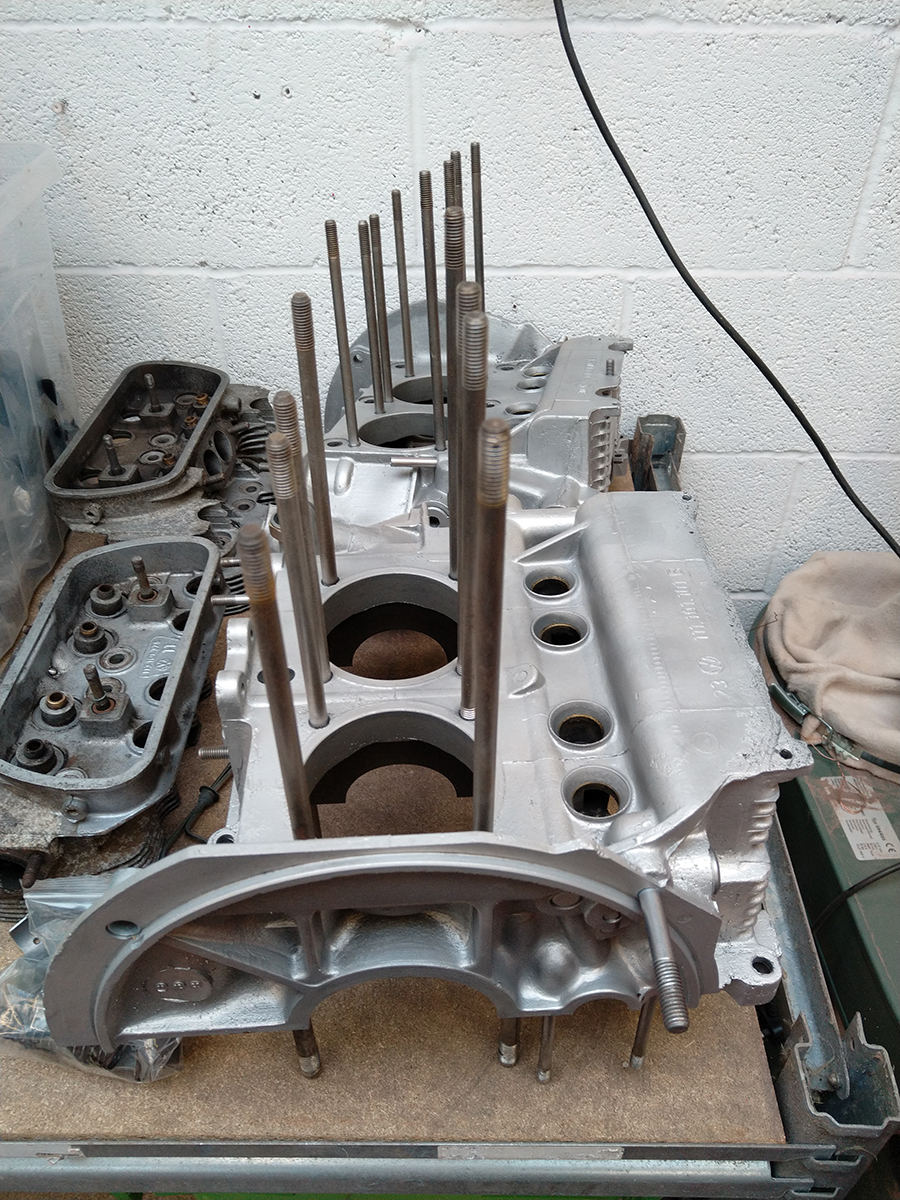

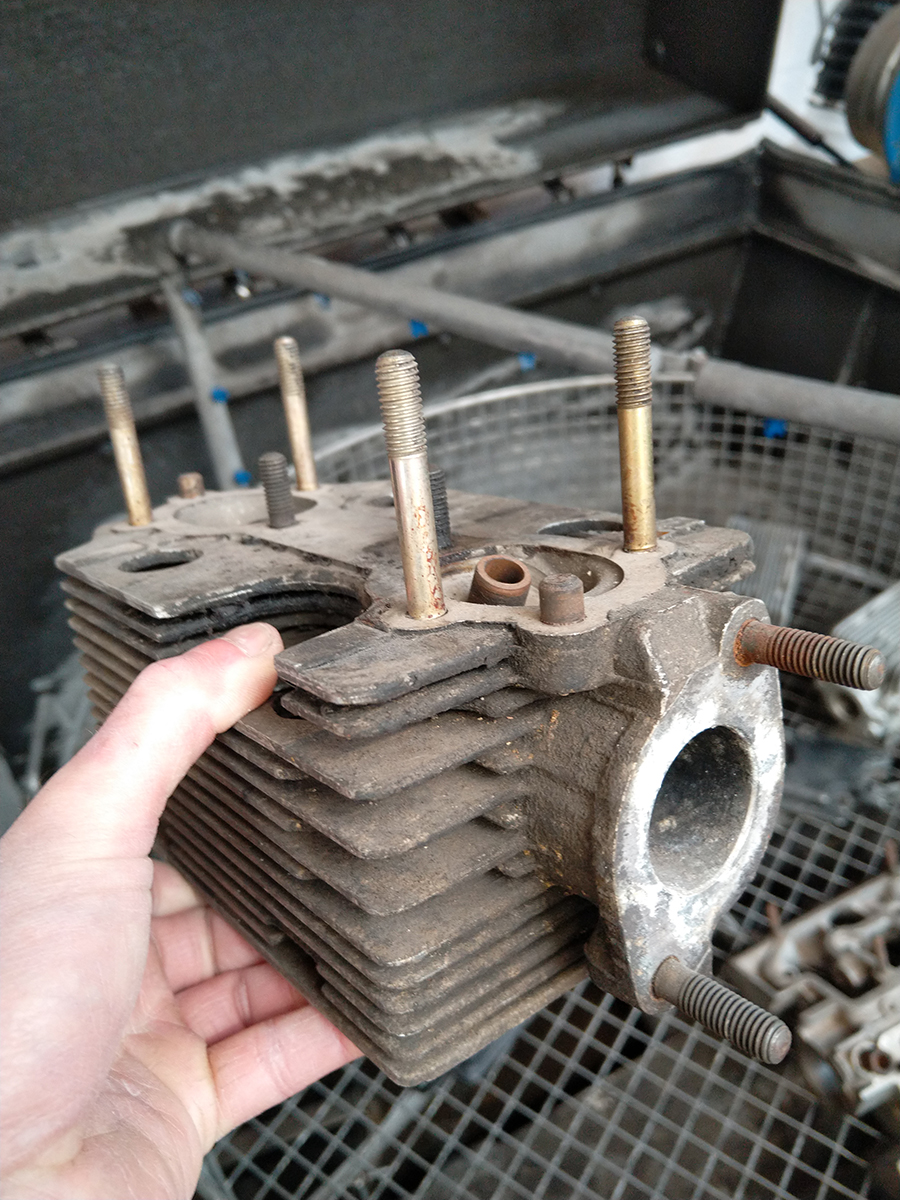

A New customer brought with a partially stripped classic Fiat 500 engine for cleaning.

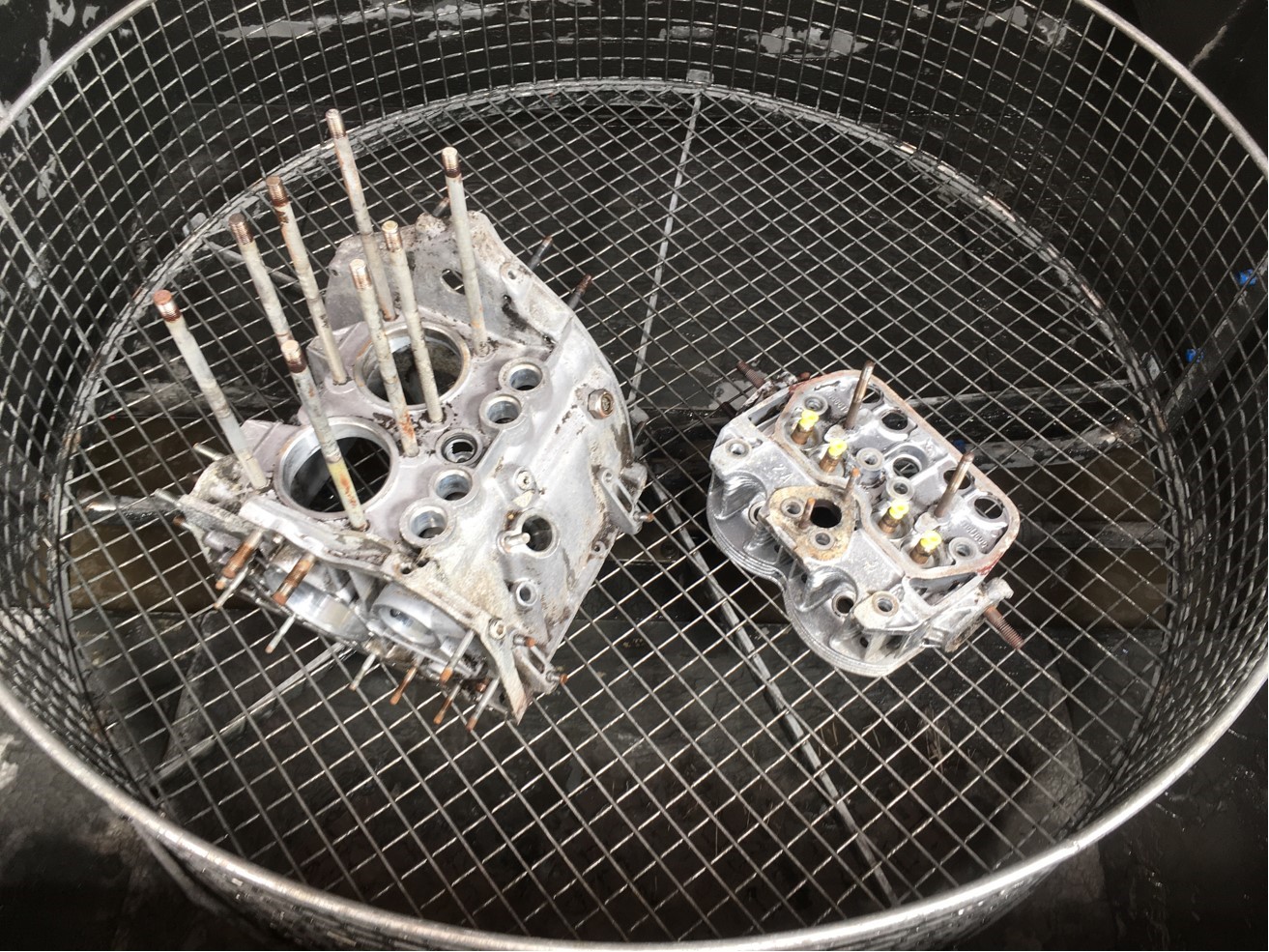

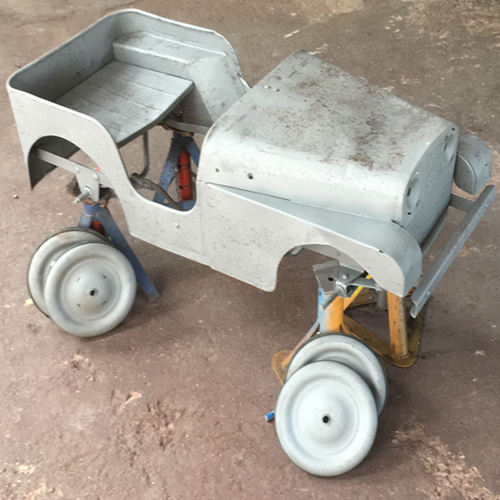

So we started with stripping down the last parts ready for a degreasing in the parts washer. This washer cleans the parts at 65’c using a mixture of water and degreaser. Some items went through several wash cycles to remove years of dirt and baked on grime.

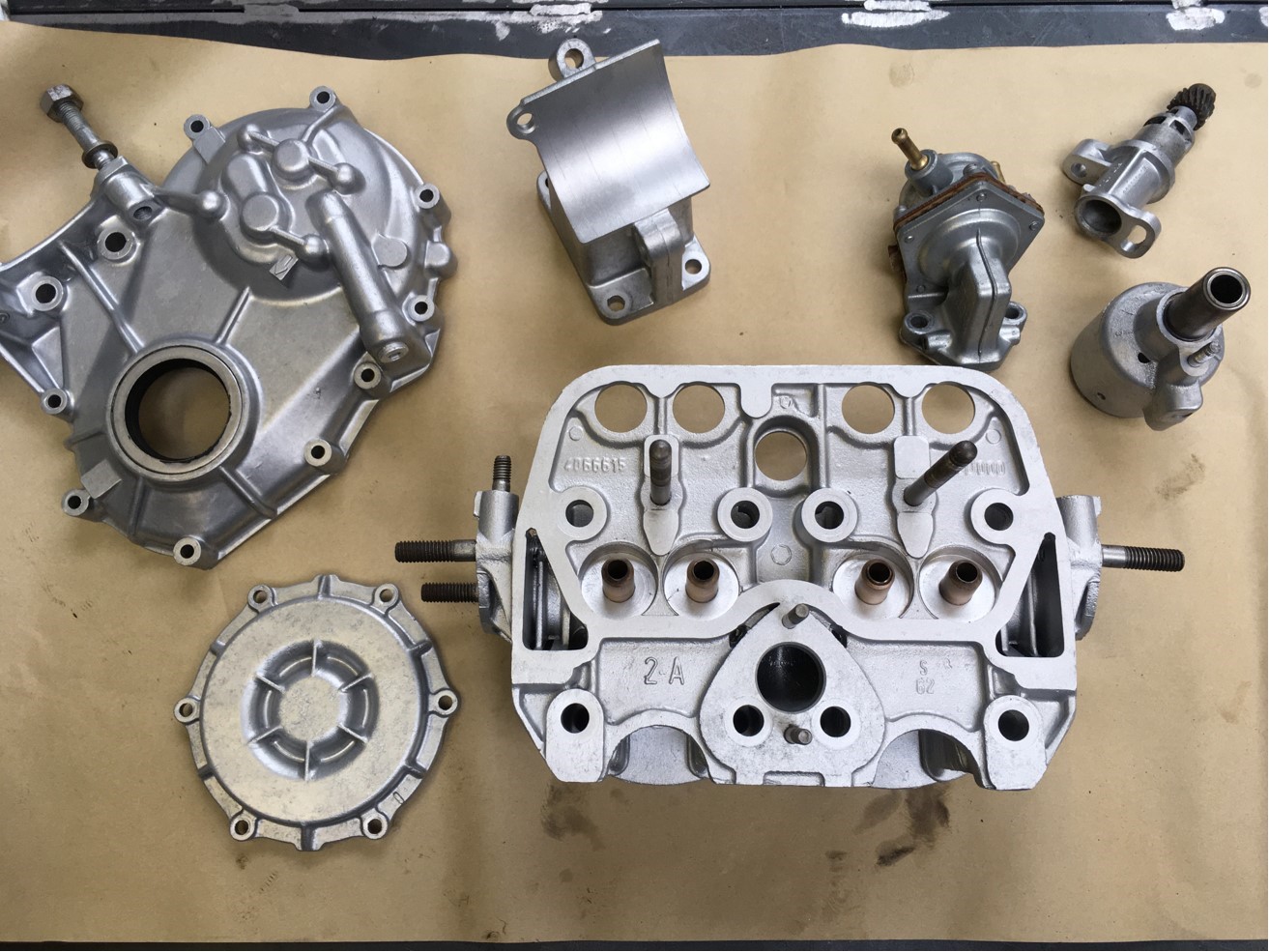

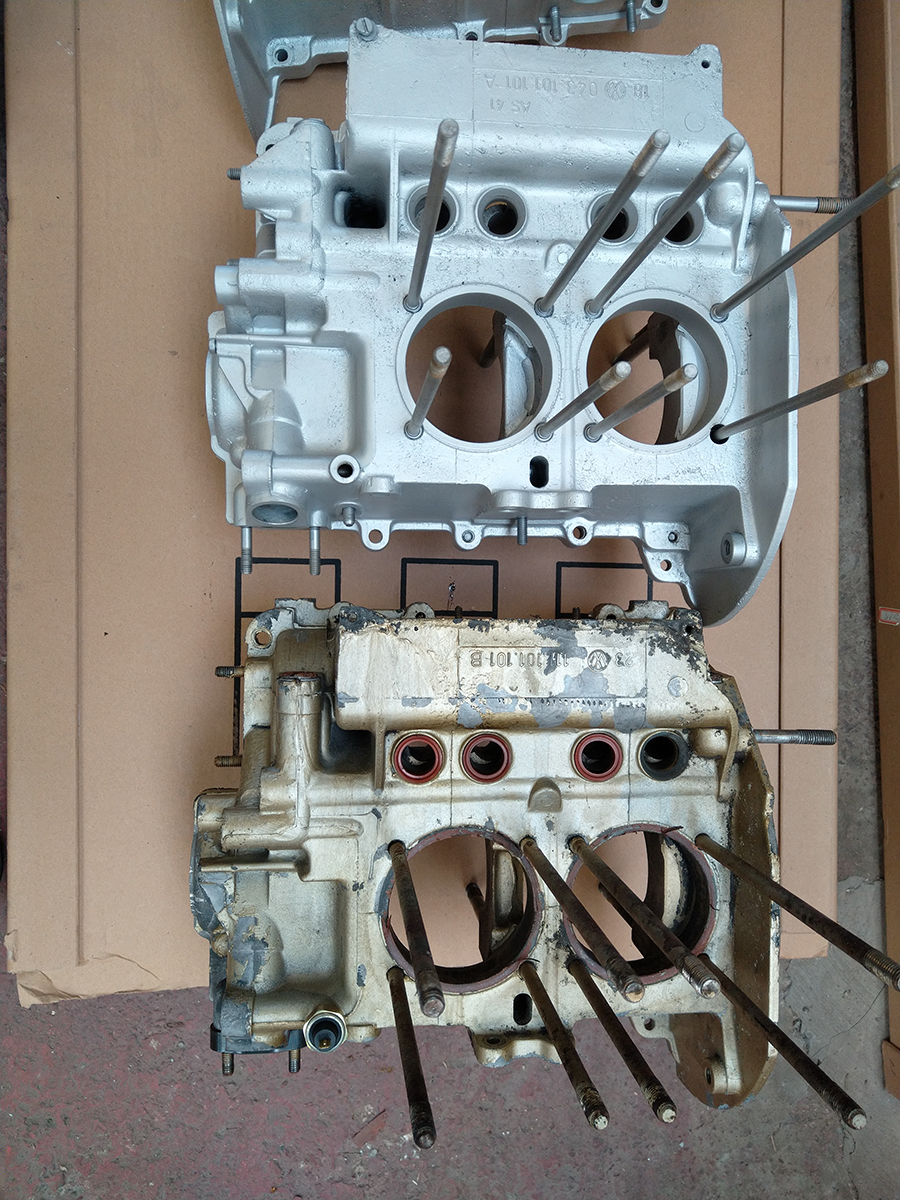

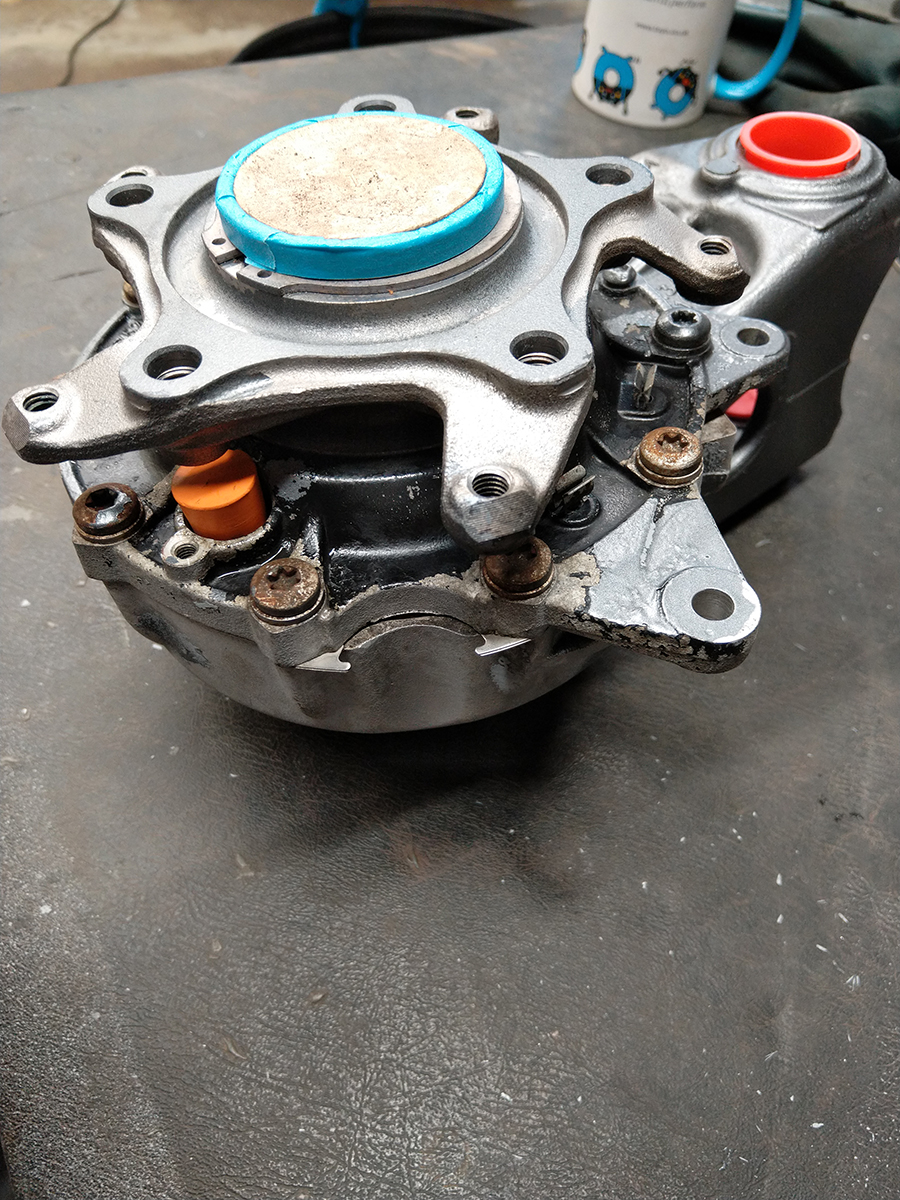

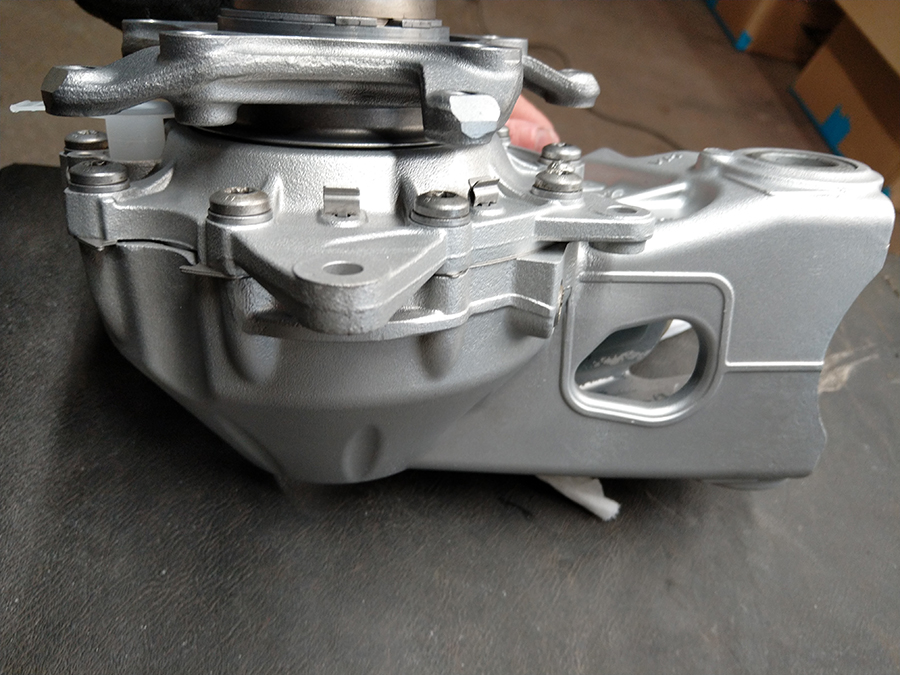

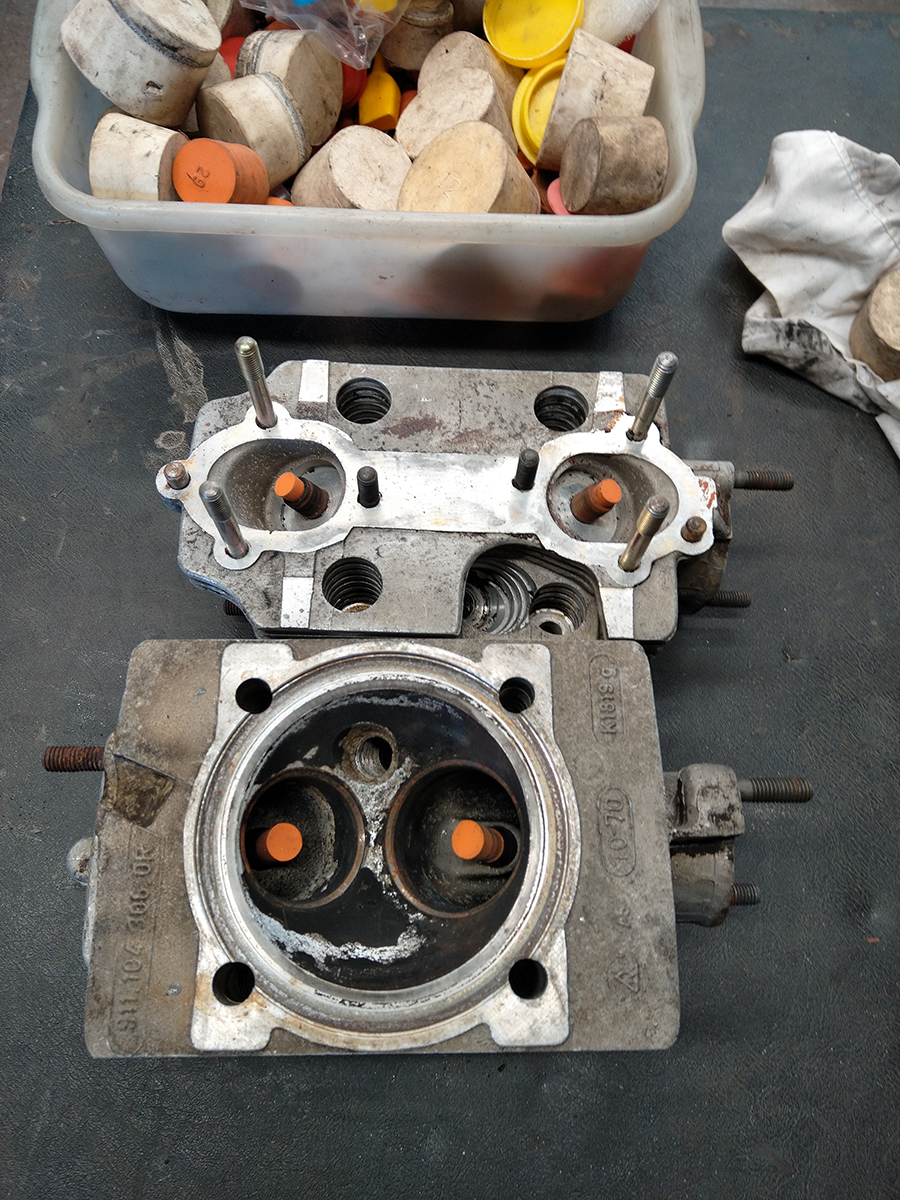

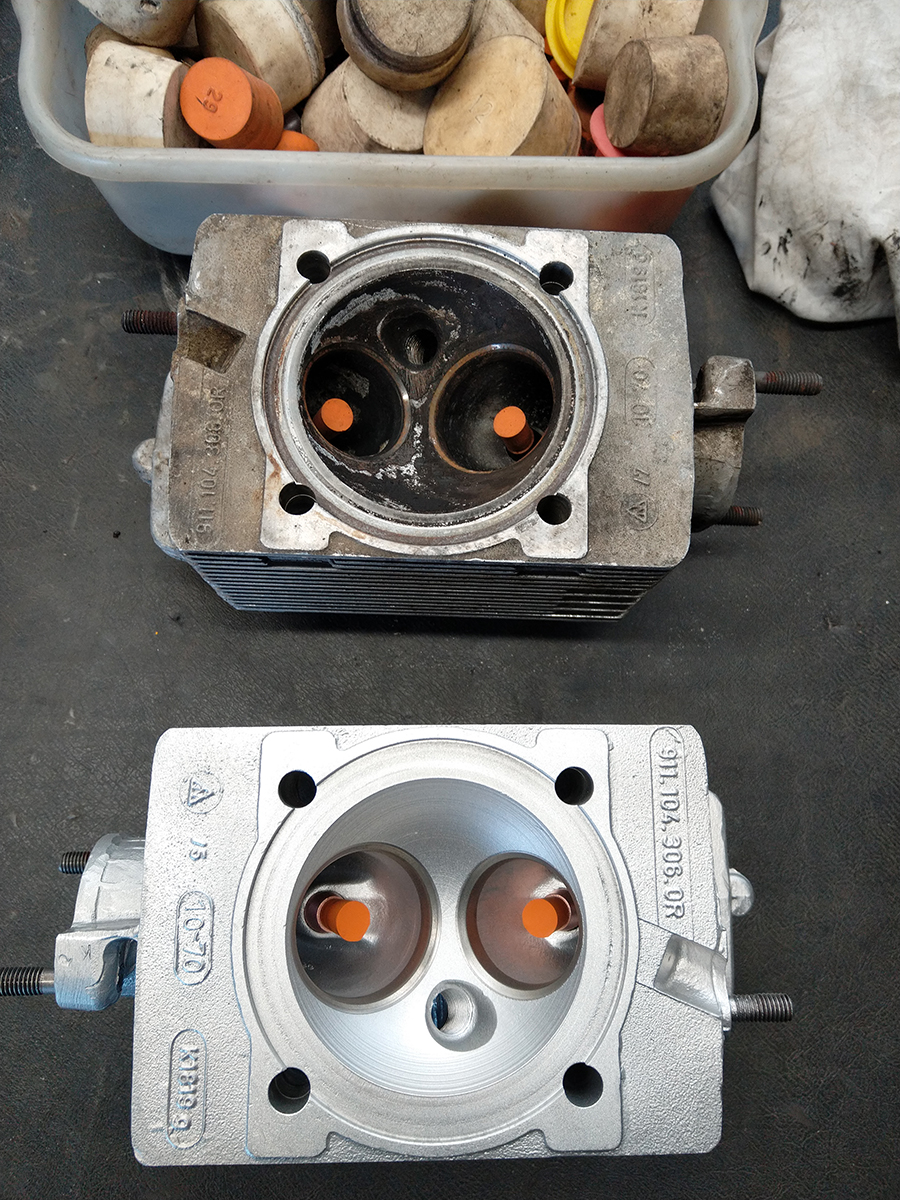

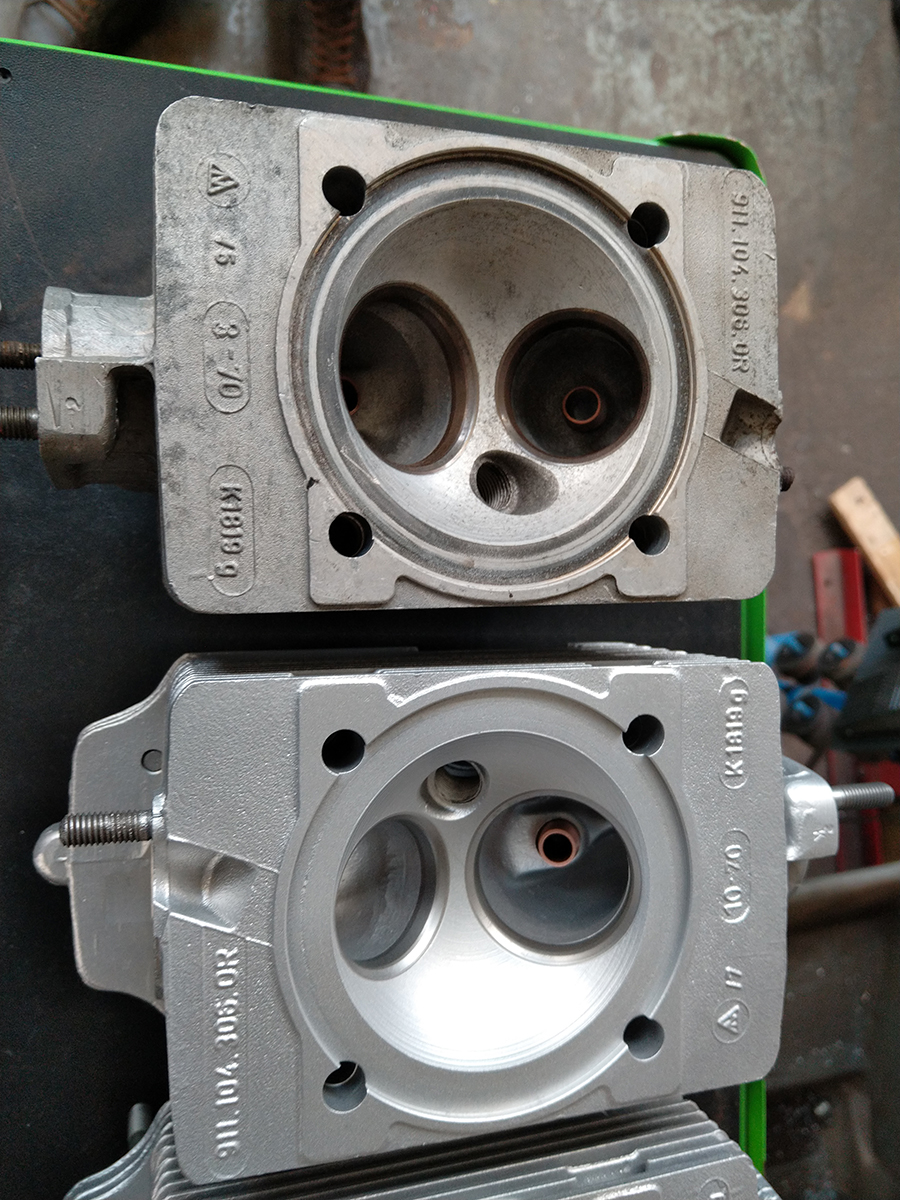

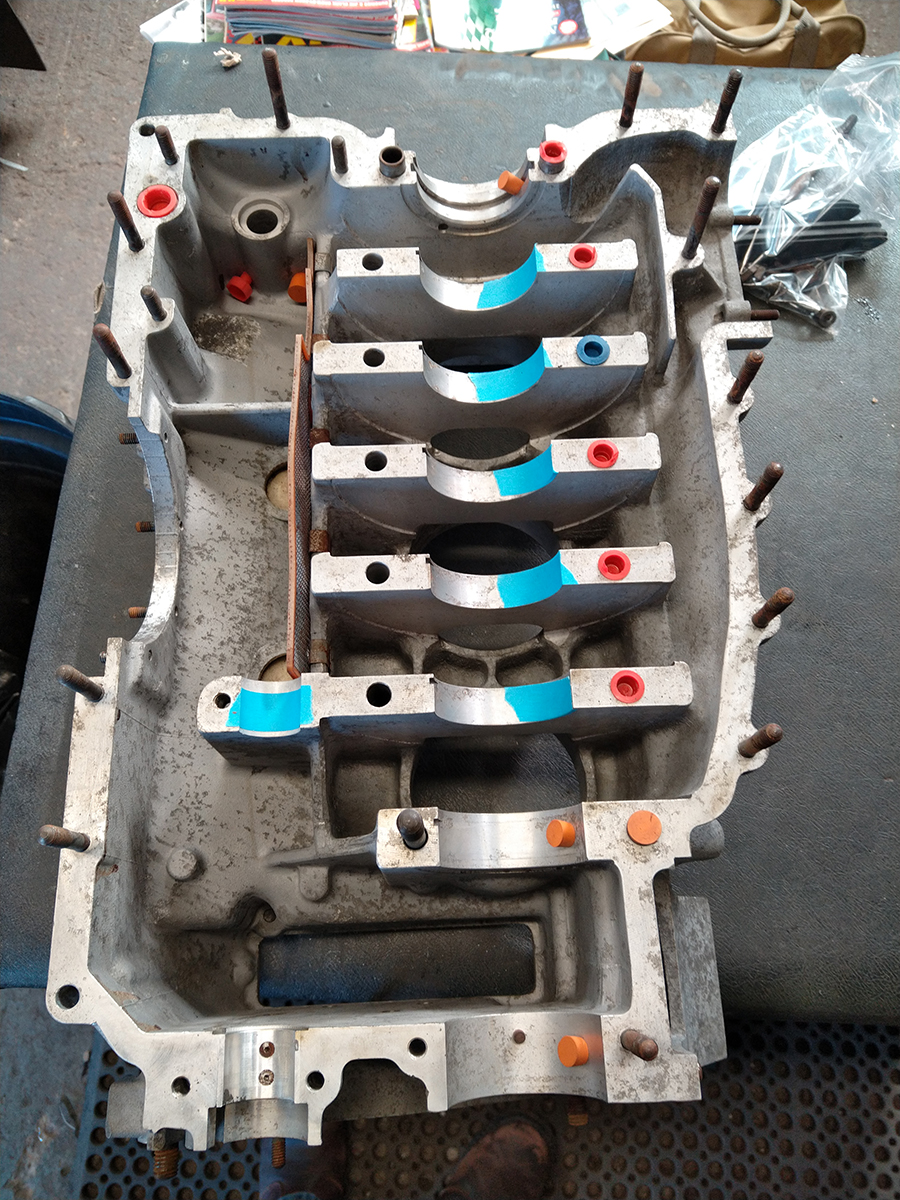

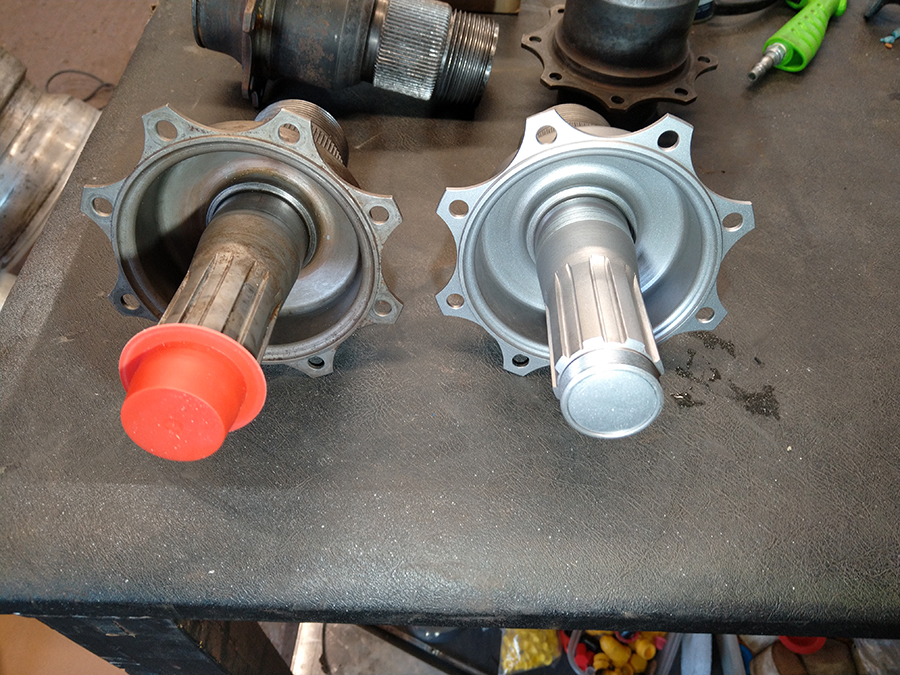

Parts were then prepared for blasting in the Vapour Blaster. All areas and drill holes are plugged or masked, where we do not want blast material getting into.

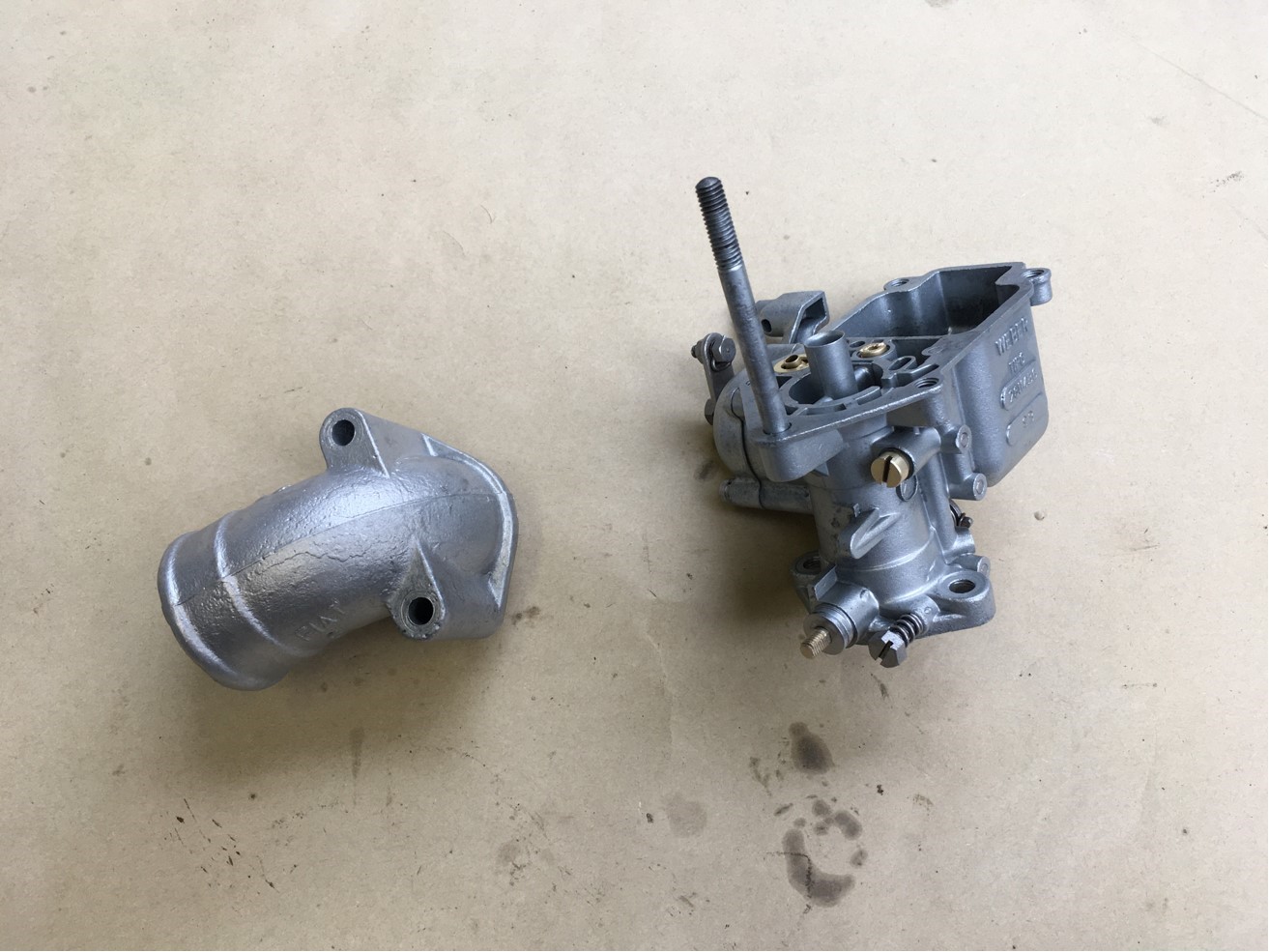

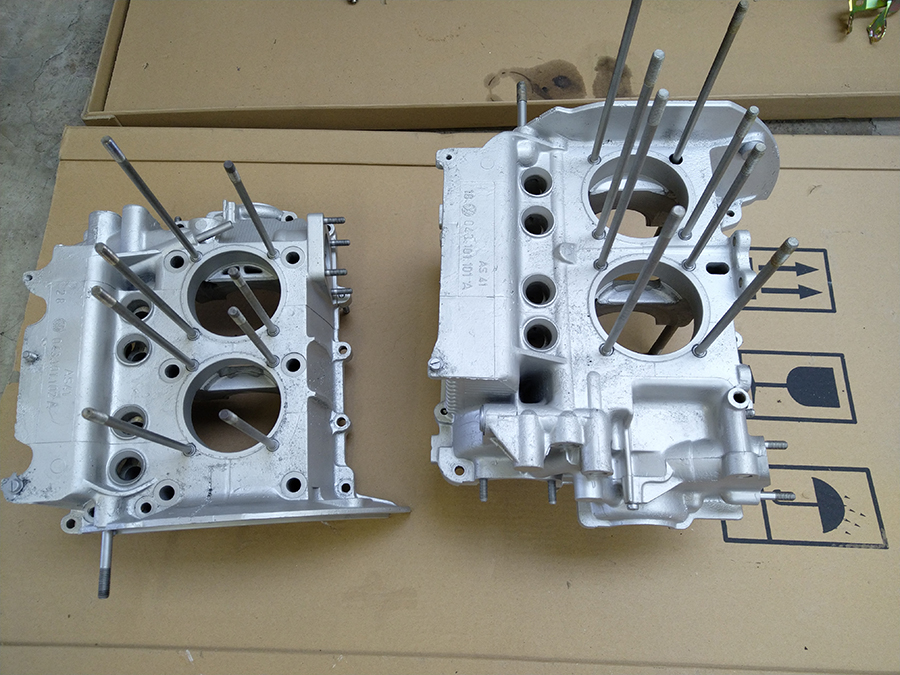

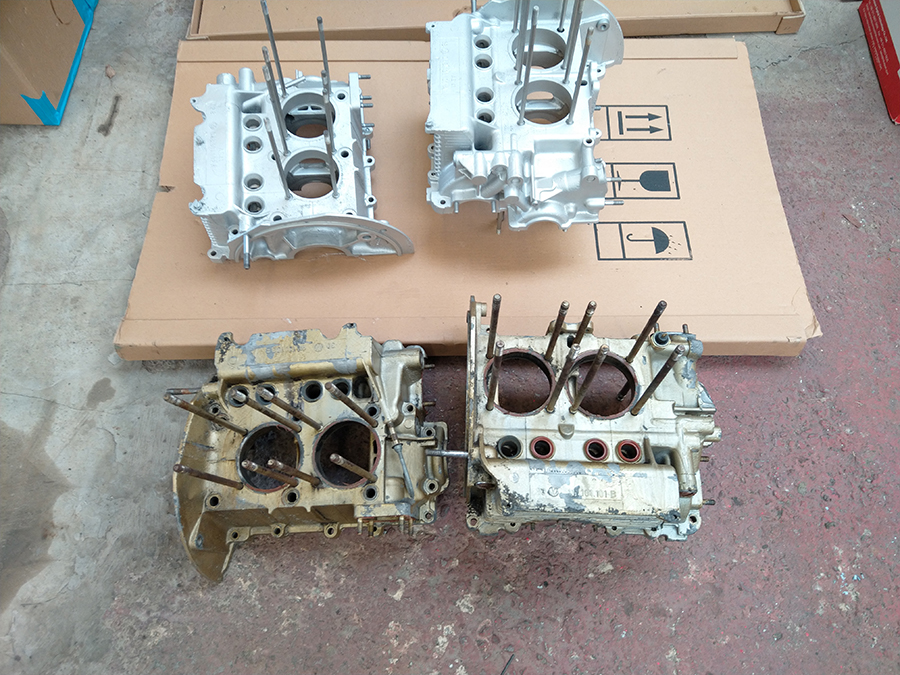

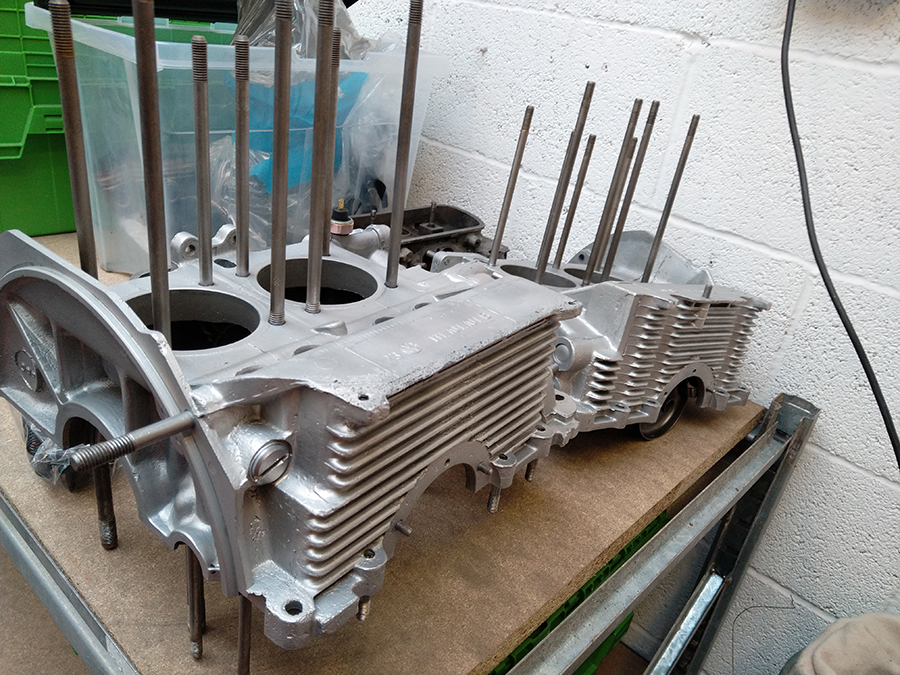

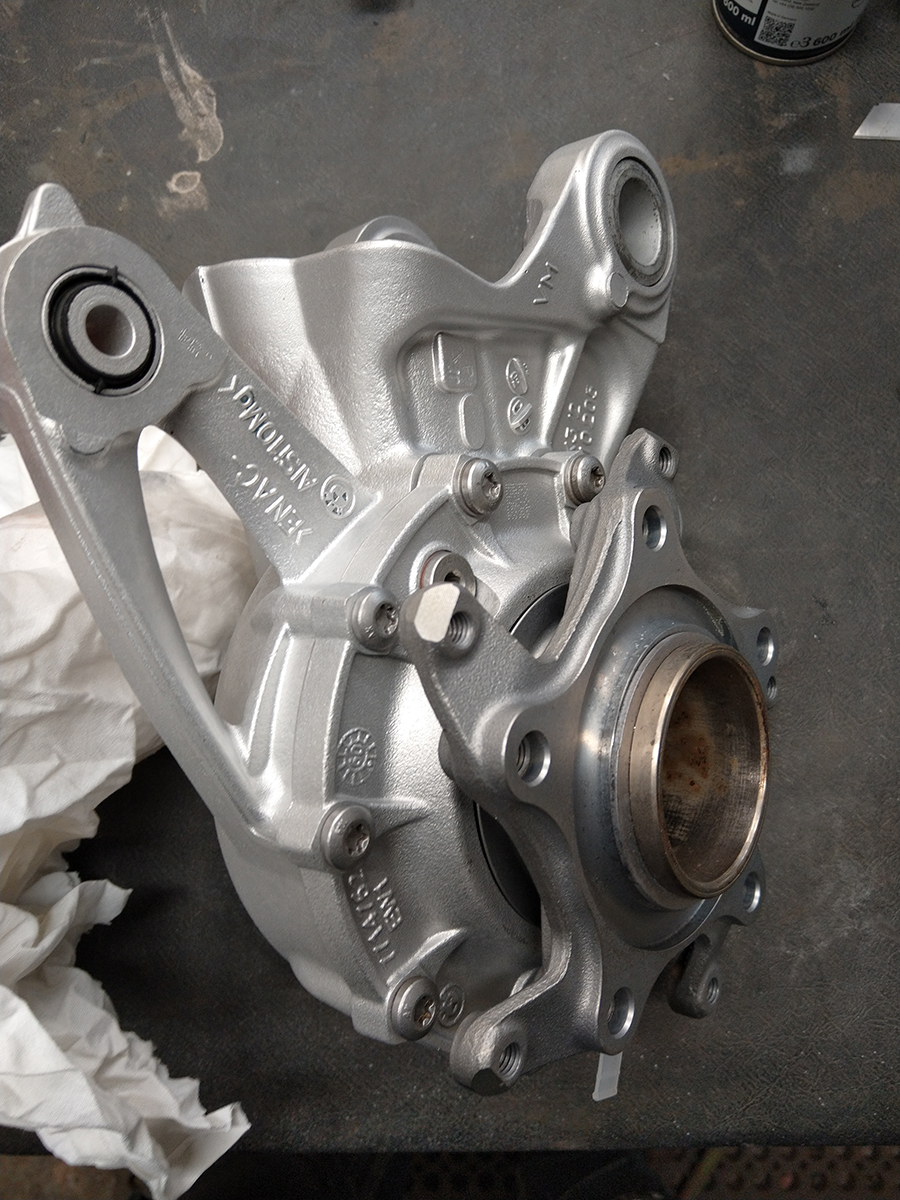

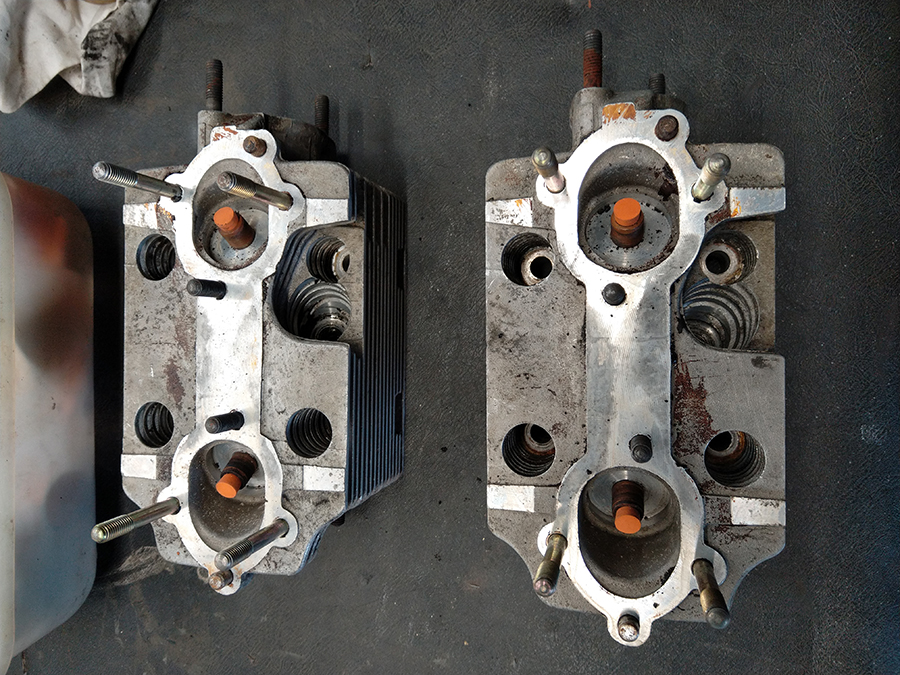

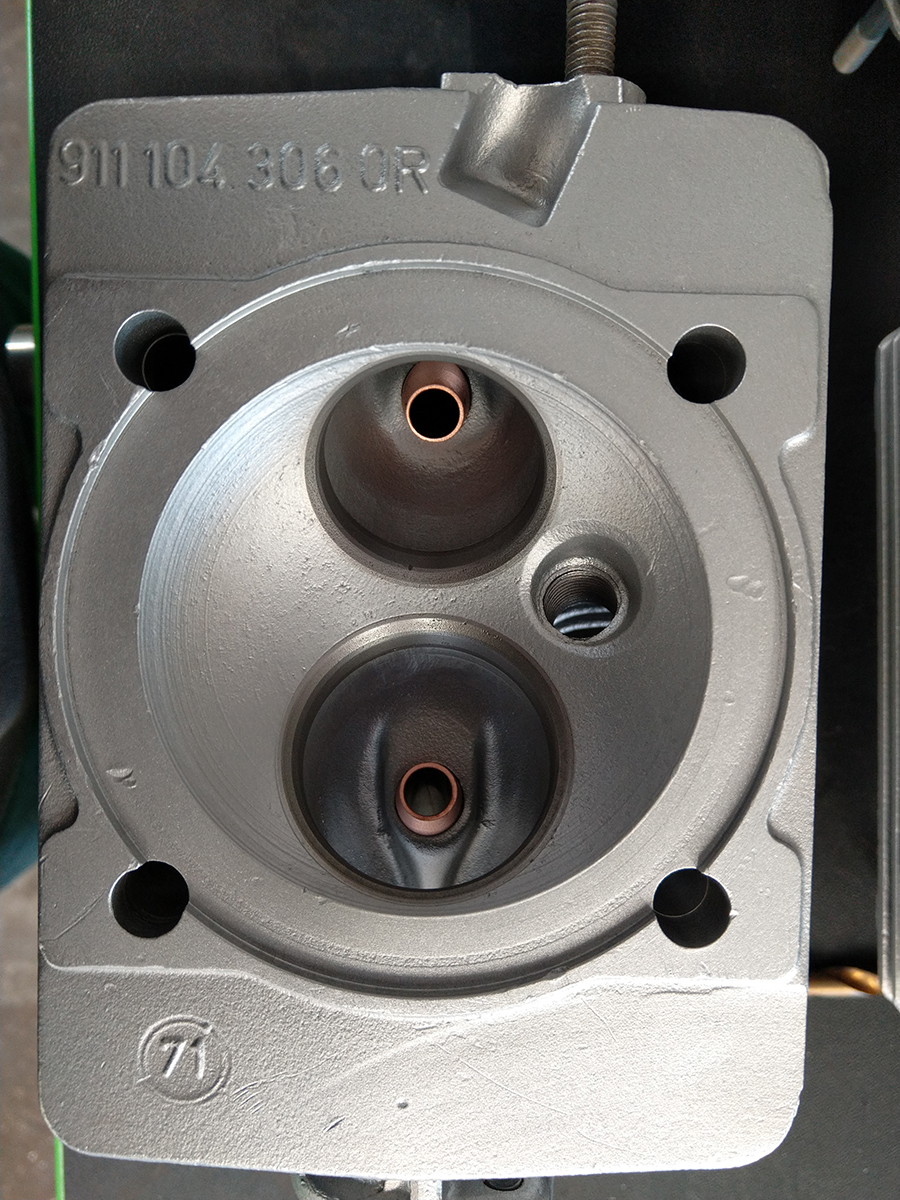

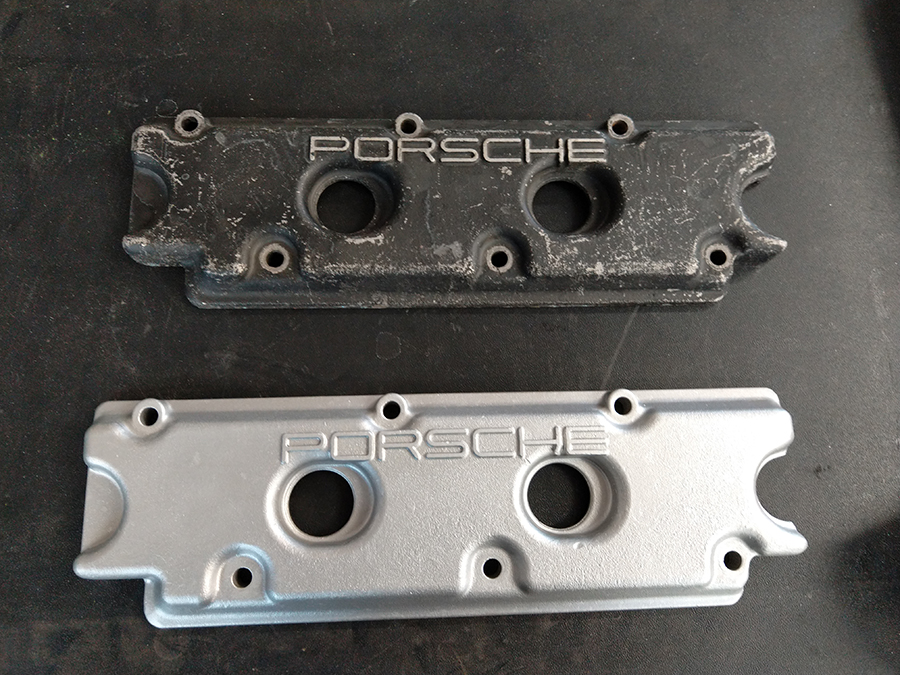

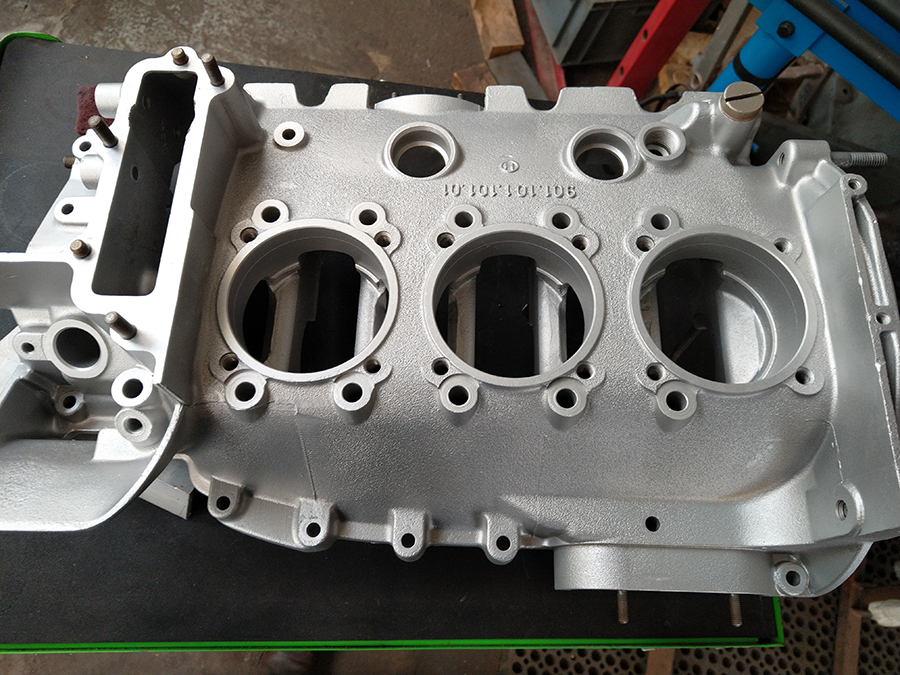

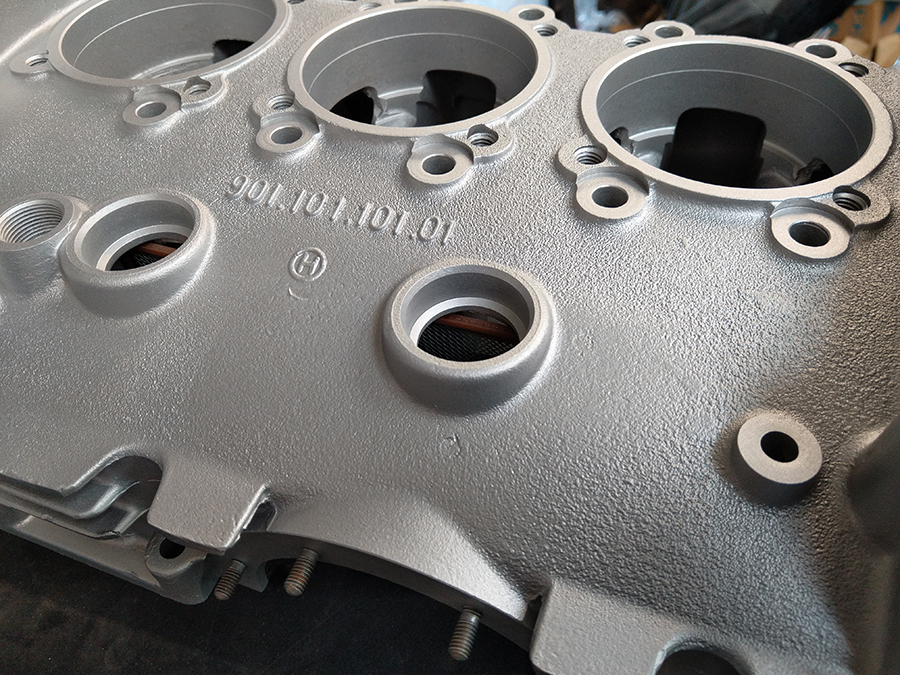

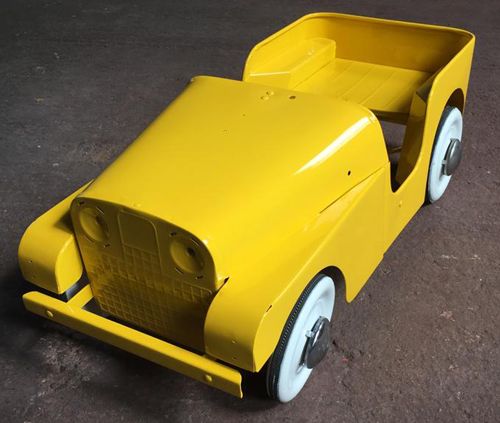

First of we tackled all the aluminium items. Glass bead was used, this is a soft polishing process to remove stubborn dirt and surface corrosion from the parts. With the result of exposing the fresh aluminium underneath. This restores the parts back to as good as they day they were cast. Parts are thoroughly checked as we go through the process and returning to the blaster to ensure all areas are completely clean.

This process of deep cleaning exposed a few issues with the cylinder head which was not apparent when it first came in. After cleaning we could see that there was damage to the spark plug thread and valve seats, which were disguised with carbon build up.

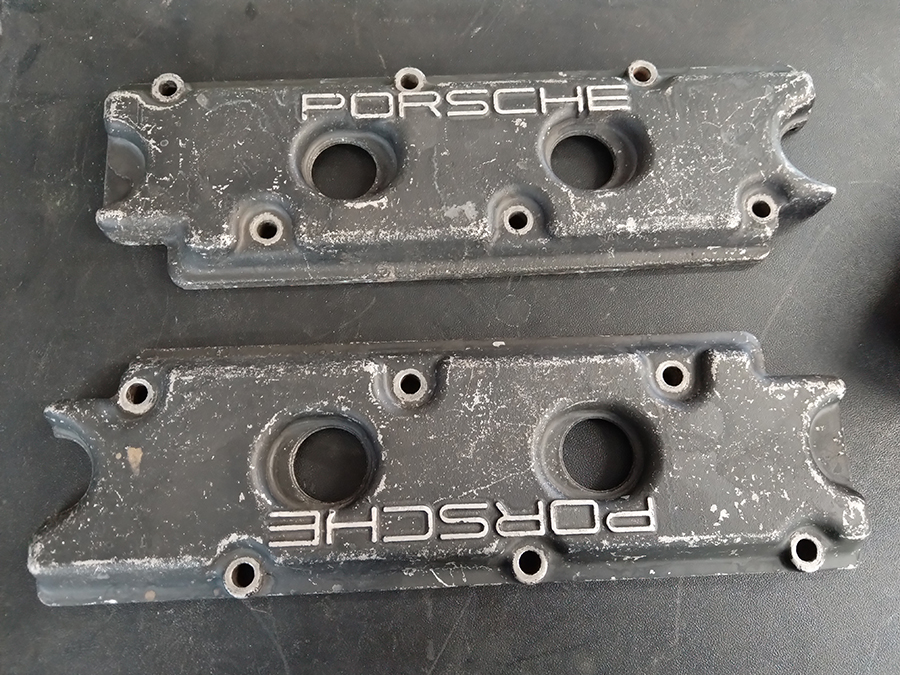

After the alloy parts had been blasted we changed the cabinet over to tackle the tin cooling pieces and sump. Using a mixture of glass and aluminium oxide to remove paint and rust. The oxide having a scouring effect. The delicate tins blasted with no risk of heat or distortion.

All items thoroughly blown off with air to ensure water and medium is removed before returned to the customer.

This project took a total of nine hours blasting and several wash cycles in the parts washer.